DOI 10.12030/j.cjee.201804096 中图分类号 X703 文献标识码 A

杨瑞丽,王晓君,吴俊斌,等. 厌氧氨氧化工艺快速启动策略及其微生物特性[J]. 环境工程学报,2018,12(12):3341-3350.

YANG Ruili, WANG Xiaojun, WU Junbin, et al. Rapid start-up strategy and microbial characteristics of anammox process[J]. Chinese Journal of Environmental Engineering,2018,12(12):3341-3350.

厌氧氨氧化工艺快速启动策略及其微生物特性

1. 中国科学院城市环境研究所,城市污染物转化重点实验室,厦门 361021

2. 中国科学院大学,北京 100049

第一作者:杨瑞丽(1989—),女,博士研究生,研究方向:水污染控制技术。E-mail:rlyang@iue.ac.cn

*

通信作者,E-mail:shchen@iue.ac.cn

收稿日期: 2018-04-13; 录用日期: 2018-10-08

基金项目: 福建省自然科学基金资助项目(2015J05115);中国科学院城市环境研究所青年前沿项目(IUEMS201404)摘 要

为探讨种泥投加及氮负荷提升方式对厌氧氨氧化(anaerobic ammonia oxidation, anammox)工艺启动中微生物丰度及群落结构的影响,采取先普通活性污泥驯化后再接种anammox种泥的方式启动anammox工艺。结果表明在活性迟滞阶段投加anammox菌种可以快速启动anammox工艺。通过缩短水力停留时间的方式增加氮负荷并可以避免直接提高进水氮浓度导致的基质毒性抑制,有利于达到更高的总氮去除负荷。稳定运行时反应器的氮去除负荷达0.51 kg·(m3·d)−1,anammox菌基因丰度为4.92×109 copies·g−1 (以VSS计),占细菌总数的2.70%。启动阶段,反应器内微生物多样性逐渐下降,检测到浮霉菌门中4个anammox菌属,以Candidatus Jettenia和Candidatus Kuenenia为主要anammox菌属。在接种污泥处于活性迟滞阶段时,结合提高进水氮浓度、缩短水力停留时间和投加anammox菌种的方式可以快速启动anammox工艺。

Rapid start-up strategy and microbial characteristics of anammox process

1. Key Laboratory of Urban Pollutant Conversion, Institute of Urban Environment, Chinese Academy of Sciences, Xiamen 361021, China

2. University of Chinese Academy of Sciences, Beijing 100049, China

第一作者:杨瑞丽(1989—),女,博士研究生,研究方向:水污染控制技术。E-mail:rlyang@iue.ac.cn

*

Corresponding author,E-mail:shchen@iue.ac.cn

Abstract

In order to investigate the effects of seed sludge inoculation and increase mode for the influent nitrogen load on the microbial abundance and community in anaerobic ammonia oxidation (anammox) reactor during a start-up period, the anammox process was initiated by inoculating acclimated activated sludge with anammox seed sludge. Results showed that adding anammox strain at a lag stage was beneficial to the rapid start-up of pilot-scale reactor. An improved nitrogen removal rate (NRR) was achieved through shortening hydraulic retention time as well as increasing the influent nitrogen load, which was an effective means to avoid the inhibition of matrix toxicity caused by increasing the influent TN concentration. In the steady running phase, the NRR of 0.51 kg·(m3·d)−1 was realized, and the gene abundance of anammox bacteria reached 4.92×109 copies·g−1(calculated by VSS), accounting for 2.70% of the total bacteria. In the start-up phase, the microbial diversity in the reactor gradually decreased, four anammox bacteria genus belonging to Planctomycetes were identified, and the dominant genus of functional bacteria were Candidatus Jettenia and Candidatus Kuenenia. The anammox process was successfully start-up with short term by inoculating anammox seed sludge, raising influent nitrogen and shorting hydraulic retention time at the lag stage of inoculation sludge.

厌氧氨氧化(anaerobic ammonia oxidation, anammox)工艺因脱氮效率高、污泥产量低、无需外加碳源等优势倍受欢迎,已被用于污泥消化液、味精废水、造酒废水和制药废水等的处理应用中[1-4]。但anammox菌具有生长速率慢、倍增时间长、环境敏感度高等缺陷,是anammox工艺实际应用的重要瓶颈之一[5-6]。为了探讨anammox工艺快速启动的方法,前人做了大量研究,如考察反应器类型[7-8]、填料类型[9]、接种污泥源[10-12]及操作参数[13]等的影响。其中,污泥源研究多是基于接种污泥中直接投加anammox种泥的启动方式。唐崇俭等[10]通过接种硝化反硝化污泥、短程硝化污泥、厌氧絮体污泥和厌氧颗粒污泥并投加2%的anammox种泥,于255 d时,成功启动了中试(2.5 m3)anammox反应器。WANG等[11]接种实验室低温保藏的anammox污泥,历时160 d,成功启动短程硝化厌氧氨氧化工艺。YE等[12]接种混合好氧、厌氧及同步部分硝化、厌氧氨氧化和反硝化污泥,于140 d时,氮去除负荷(nitrogen removal rate, NRR)达0.44 kg·(m3·d)−1。尽管将anammox污泥跟其他污泥混合后同时投加,增加了种泥中anammox菌的起始丰度,但随着菌体自溶阶段的运行,活性污泥解体必然会产生一定量的有机物而抑制anammox菌生长[2,12,14]。此时若首先投加普通活性污泥,待启动过程的停滞阶段再投加anammox种泥,可以有效避免有机物对其生长的抑制,且大大减弱了其他细菌跟anammox菌的竞争。另一方面,由于氨氮(NH4+-N)和亚硝氮(NO2−-N)对anammox菌都有毒害作用,如果单纯通过提高进水NH4+-N和NO2−-N浓度来增加进水氮负荷(nitrogen loading rate, NLR),则可能导致基质毒性抑制[2,15],而通过缩短水力停留时间(hydraulic retention time, HRT)则可避免,且该方式少有研究。

高通量测序技术可同时获取上百万条DNA,并将其准确归类,是鉴定微生物的有效手段[16]。对anammox反应器进行功能菌定量分析和微生物群落结构分析,可以从功能菌群丰度和群落结构2个方面研究反应器启动过程微生物群落演化,为判断反应器成功启动与否提供直接依据[16-17],并为反应器的稳定运行和调控提供科学依据。本研究探索采取先普通活性污泥驯化后再接种anammox种泥的方式快速启动anammox工艺,并采用先逐步提高进水总氮(total nitrogen, TN)浓度后缩短HRT的方法提高进水NLR。同时利用Illumina Miseq测序和实时定量聚合酶链式反应(polymerase chain reaction, PCR)方法,分析了启动过程中污泥微生物群落变化,为深入认识anammox工艺的启动进程提供依据。

1 材料和方法

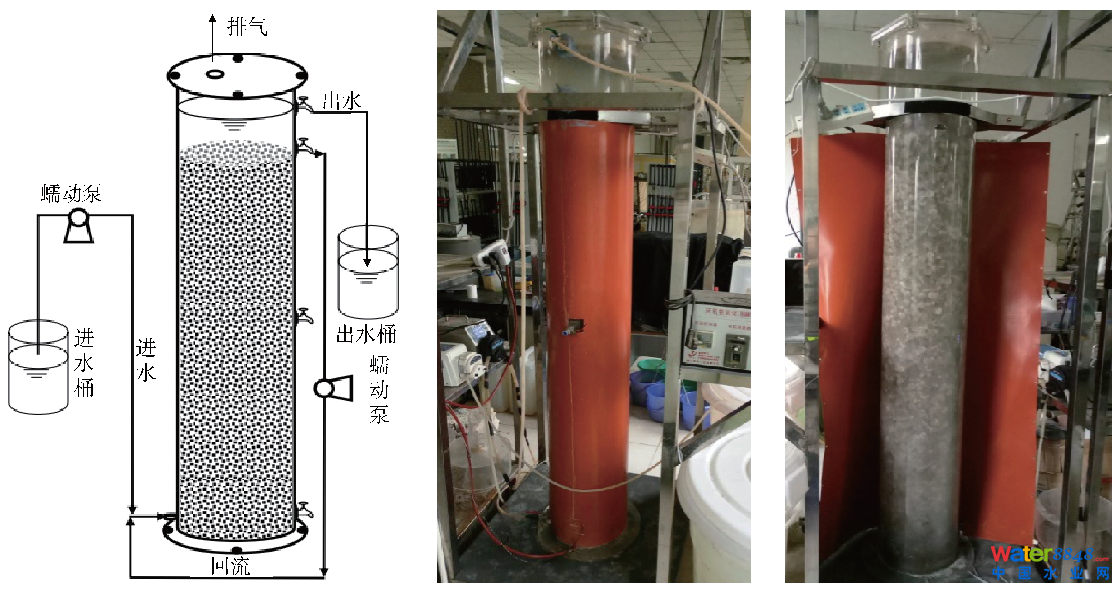

1.1 实验装置

实验采用升流式厌氧氨氧化反应器,实验装置示意图及反应器照片见图1。反应器有效容积100 L,顶部加盖,由螺钉和胶条密封,并预留有排气孔。距底部2 cm和顶部10 cm处分别设有进水口和出水口,中部和底部设有污泥采样口。反应器内部装填鲍尔环填料。内设回流装置,强化反应器内溶液混合,预防进水端反应物浓度过高,也起到防止进水口堵塞的作用。反应器进水pH经0.1 mol·L−1盐酸调节至7.2左右,外部包裹电加热带以保证内部恒温(35±2) °C,避光运行,维持anammox菌适宜的生长环境。

1.2 实验条件和运行策略

实验用水为人工配制的模拟废水,具体组成见表1。其中,进水NH4+-N和NO2−-N浓度均为30~500 mg·L−1,NO3−-N浓度维持在100 mg·L−1以内。另外,微量元素配方为ZnSO4·7H2O 0.43 g·L−1、CoCl2·6H2O 0.24 g·L−1、MnCl2·4H2O 0.99 g·L−1、CuSO4·5H2O 0.25 g·L−1、NaMoO4·2H2O 0.043 g·L−1、NiCl2·6H2O 0.20 g·L−1、KH2PO4 20 g·L−1、H3BO3 0.014 g·L−1,并加入EDTA 20 g·L−1以促进微量元素的溶解。采集进出水水样经0.45 μm滤膜过滤后,分别采用纳氏试剂法、N-(1-萘基)乙二胺分光光度法和紫外分光光度法测定样品中的NH4+-N、NO2−-N和NO3−-N [18]。pH采用便携式pH计(FG2-FK, METTLER TOLEDO, USA)测定;污泥样品MLSS、MLVSS均按标准方法[19]测定。

表1 模拟废水成分

Table 1 Chemical composition of synthetic wastewater

Table 1 Chemical composition of synthetic wastewater

anammox工艺启动过程主要分为4个阶段,分别是Ⅰ菌体自溶、Ⅱ活性迟滞、Ⅲ活性提高和Ⅳ活性稳定阶段[7,20]。本研究采用2阶段接种方式启动anammox反应器。首先接种80 L取自厦门市某污水处理厂二沉池的活性污泥,使反应器中ρ(SS)=47.05 g·L−1,ρ(VSS)=13.19 g·L−1。等到污泥处于anammox活性迟滞阶段时(第60 天),投加已培养10个月具有anammox活性的种泥(泥色微红,ρ(SS)=26.69 g·L−1,ρ(VSS)=13.52 g·L−1),接种量为20 L。通过逐步提高进水TN浓度(41~116 d)和缩短HRT(117~172 d)来提高反应器NLR,具体运行参数见表2。

表2 反应器各阶段运行参数

Table 2 Reactor operation parameters of each phase

Table 2 Reactor operation parameters of each phase

1.3 实验装置DNA提取、实时定量PCR分析与多样性测定

1.3.1 DNA提取

分别在工艺启动0、59、76、83、94、104、116、126、138、156和172 d时,采集污泥混合液。经30 min静沉后,称取500 mg污泥样品,使用FastDNA™ SPIN Kit for Soil(LLC, MP Biomedicals, USA)提取试剂盒,按其操作步骤提取污泥样品中总DNA。DNA经1%琼脂糖凝胶电泳和Nanodrop(ND1000, Gene Company Limited, China)检测其纯度和浓度后进行实时定量PCR实验,并从中选取0、59、104和172 d的DNA样品进行Illumina高通量测序。

1.3.2 实时定量PCR分析

实时定量PCR是一种可以准确定量功能基因拷贝数,进而计算功能菌丰度的实验方法。本实验采用Roche LightCycler® 480 Ⅱ(Roche Diagnostics Ltd., Rotkreuz, Swltzerland)实时荧光定量系统进行丰度分析,采用20 μL反应体系,具体配置为:SYBR Green Ⅰ Master(LightCycler® 480, mannheim, Germany)10 μL;前后引物各0.8 μL;质粒或DNA样品1 μL;去离子水 7.4 μL。其中,全细菌定量引物为通用引物341F:534R[21],而anammox菌采用特异性引物Amx808F(5'-ARC YGT AAA CGA TGG GCA CTA A-3')和Amx1040R (5'-CAG CCA TGC AAC ACC TGT RAT A-3')[21-22]。实时定量PCR运行程序为3步法:95 °C预变性5 min,35个循环(95 °C变性30 s,45 °C退火30 s,72 °C延伸30 s),72 °C终延伸10 min,最后进行溶解曲线分析,并计算anammox菌的绝对丰度及其在总细菌中的占比。

1.3.3 Illumina高通量测序

取样品16S rRNA基因中的V4~V5区,选用引物515F (5′-GTG CCA GCM GCC GCG G-3′)和907R (5′-CCG TCA ATT CMT TTR AGT TT-3′)进行扩增,扩增产物经2%琼脂糖凝胶电泳质控,并均一化后,进行Miseq文库构建,并采用Illumina Miseq测序平台对样品进行高通量测序。源数据经质控处理后,筛选高质量数据用MOTHUR软件程序进行分析。

2 结果与讨论

2.1 厌氧氨氧化工艺启动过程脱氮性能变化

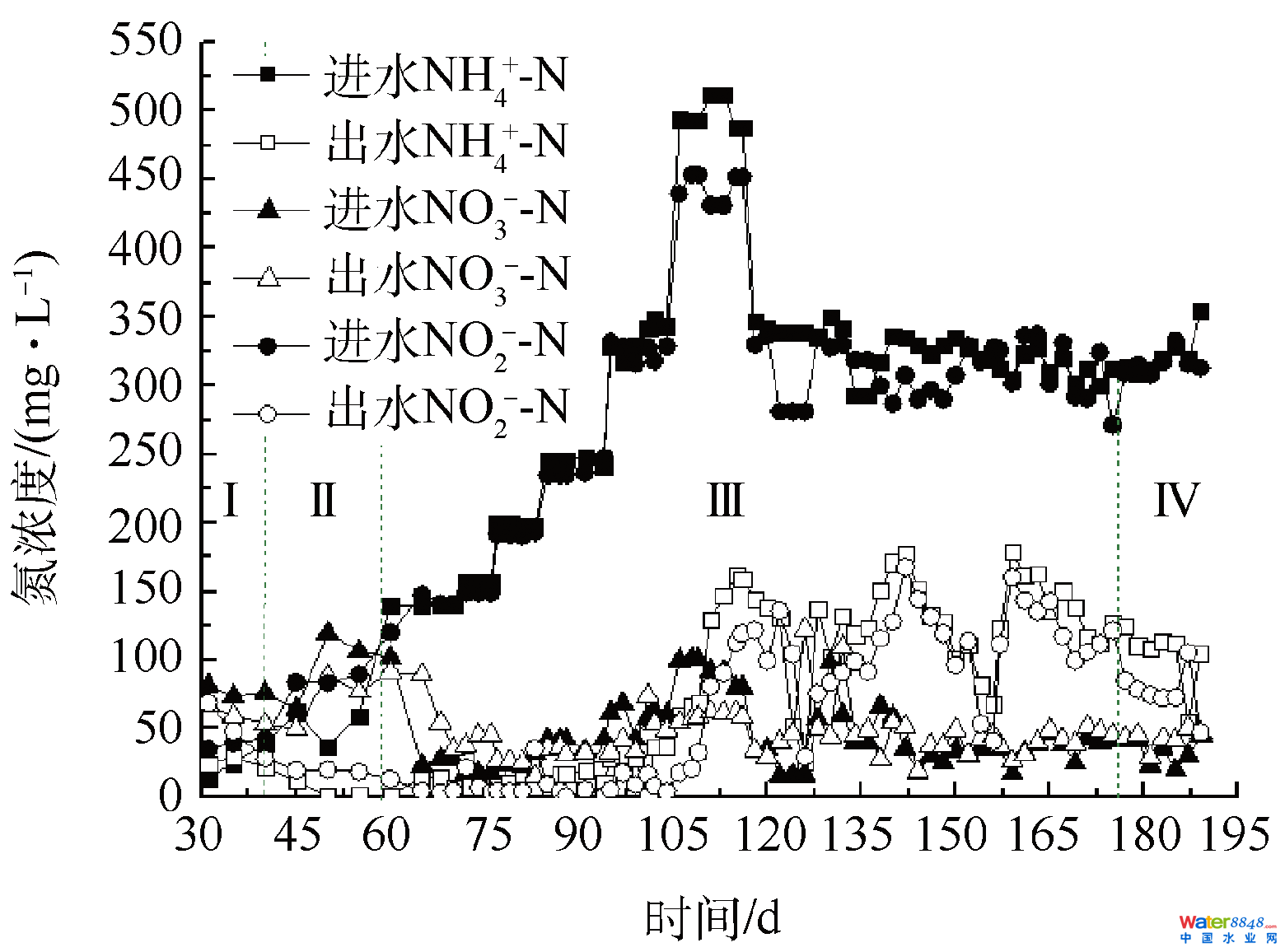

图2为anammox反应器启动过程各氮物质浓度变化。反应器运行初期1~40 d为阶段Ⅰ,出水NH4+-N和NO2−-N浓度均高于进水,为微生物的自溶解体阶段[5,20]。该阶段出水NO2−-N浓度逐渐下降,可能是反应器中共存有氨氧化菌(ammonia oxidizing bacteria, AOB)和反硝化菌(denitrification bacteria, DNB),其中AOB利用进水中微量的溶解氧将NO2−-N转化为NO3−-N,DNB则将NO3−-N和NO2−-N还原为N2,使NO2−-N浓度下降[5,23]。CHAMCHOI等[7] 、GUO等[24]和BI等[25]研究表明,工艺启动初期,反应器内部微生物出现菌体细胞自溶,释放出大量的有机物和NH4+-N,同时有机氮被分解,为异养微生物提供碳源,使出水NH4+-N和NO2−-N浓度高于进水,与本研究结果一致。反应器运行41~59 d为阶段Ⅱ,此时出水NH4+-N和NO2−-N同步去除,表明anammox菌已显示出一定活性[5,20,26]。ΔNO2−-N/ΔNH4+-N值平均为1.14,略低于STROUS等[27]报道的值,且出水NO3−-N浓度低于进水,说明反应器内仍有一部分DNB利用残留有机质做电子供体还原NO3−-N为N2[28]。

图2 中试厌氧氨氧化工艺启动中进出水氮浓度变化

Fig. 2 Nitrogen variation of influent and effluent during start-up of anammox process in a pilot-scale reactor

Fig. 2 Nitrogen variation of influent and effluent during start-up of anammox process in a pilot-scale reactor

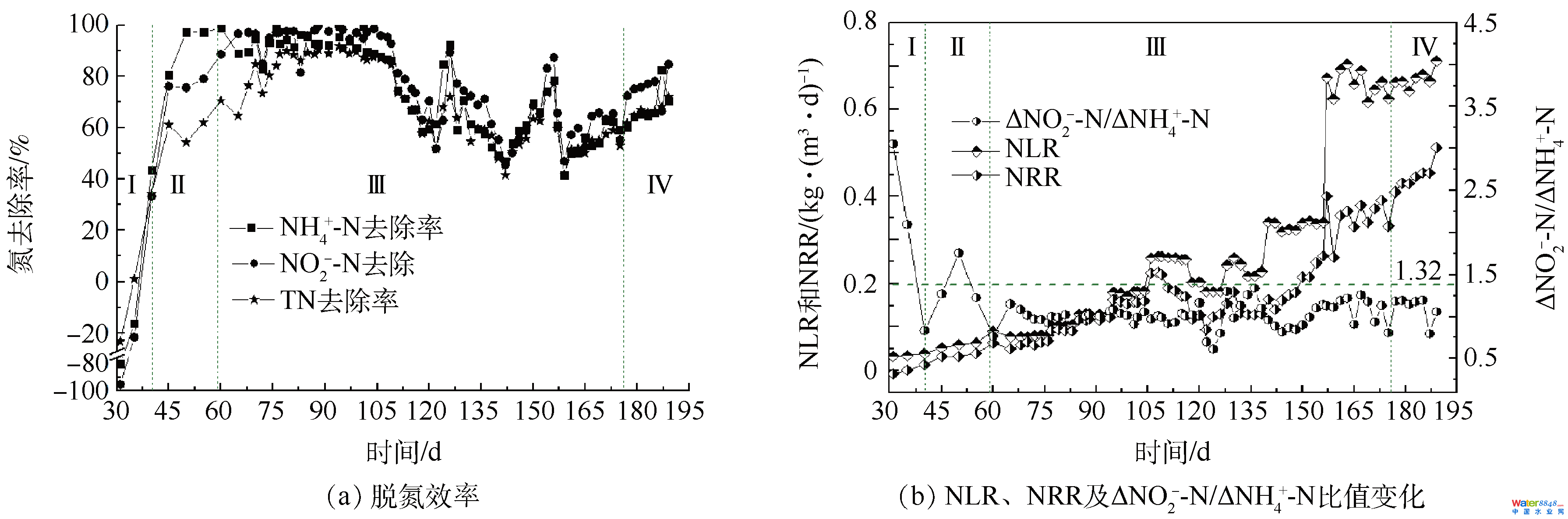

反应器运行第60 天,再接种20 L富含anammox菌的种泥,然后以提高进水氮浓度和缩短HRT的方式提高反应器NLR,此阶段为阶段Ⅲ。结合试厌氧氨氧化工艺启动中进出水氮浓度变化(图2)和厌氧氨氧化工艺启动中脱氮效率、NLR、NRR及ΔNO2−-N/ΔNH4+-N比值的变化(图3)可知,接种anammox种泥起到了稳定反应器脱氮性能的作用,尽管在接种anammox种泥的同时,提高了进水TN浓度,也可使反应器于10 d内TN去除率从64.70%提升至84.77%,促进了反应器的快速启动[29]。这是因为经过阶段Ⅰ和Ⅱ的培养后,反应器内可降解的有机碳源大幅降低,与anammox菌竞争的异养微生物显著减少,此时添加有anammox活性的种泥可使反应器内anammox菌丰度迅速增加,利于anammox活性的快速提升[30]。唐崇俭等[10]和WANG等[11]指出anammox种泥的添加是anammox工艺脱氮性能增强的关键。

图3 厌氧氨氧化工艺启动中脱氮效率、NLR、NRR及ΔNO2−-N/ΔNH4+-N比值变化

Fig. 3 Nitrogen removal performance of anammox reactor, including nitrogen removal efficiency, NLR, NRR and Δnitrite/Δammonium

Fig. 3 Nitrogen removal performance of anammox reactor, including nitrogen removal efficiency, NLR, NRR and Δnitrite/Δammonium

当进水TN浓度≤700 mg·L−1(60~104 d)时,虽然进水TN浓度持续增加,但反应器出水氮浓度并无明显变化,反应器NRR达0.16 kg·(m3·d)−1。当进水TN浓度达1 000 mg·L−1(105~116 d)时,TN去除率于12 d内由87.51%下降至66.89%,NRR较105 d时下降了24.16%。第116天,出水NH4+-N和NO2−-N浓度分别为104 d时的4.26和26.67倍,这可能是因为过高的NO2−-N浓度抑制了anammox菌的活性。曹雁等[17]也发现,当进水NH4+-N和NO2−-N浓度分别达到330 mg·L−1和430 mg·L−1时,反应器出水水质突然恶化。研究表明,NO2−-N对anammox菌的影响高于NH4+-N [31],NH4+-N浓度低于1 000 mg·L−1时不会抑制anammox菌活性,而NO2−-N高于280 mg·L−1时便会产生抑制[32],DAPENA-MORA等[33]也表明350 mg·L−1的NO2−-N会抑制anammox菌50%的活性。为确保反应器快速恢复并稳定运行,在反应器运行117~126 d期间,将进水TN浓度降至700 mg·L−1,同时HRT由原来的4 d缩短为3.5 d,NLR也相应地由0.25 kg·(m3·d)−1降至0.19 kg·(m3·d)−1。由于进水基质浓度降低对anammox菌的抑制作用解除,反应器anammox活性快速恢复,10 d内NH4+-N、NO2−-N和TN去除率分别由67.27%、73.55%和66.89%快速升至92.41%、89.47%和72.05%。反应器运行127~172 d,HRT由3.5 d缩短至2 d,进而缩短至1 d,每次缩短HRT,反应器出水水质都有一个恶化进而恢复的过程,表明功能菌群逐步适应着生长环境的变化[34]。第172天,NH4+-N、NO2−-N和TN去除率及NRR分别达60.82%、65.16%、57.70%和0.38 kg·(m3·d)−1。与提高氮浓度对反应器脱氮性能的影响相比,缩短HRT对提高反应器脱氮性能作用更大。研究表明,缩短HRT一方面会加速混合反应基质,另一方面会加大系统水流剪切力,这有利于anammox反应器的运行[35-36]。

阶段Ⅳ(173~189 d)为anammox反应器的活性稳定阶段,最终NH4+-N、NO2−-N和TN去除率分别稳定在76.50%、76.45%和70.04%左右,NRR达0.51 kg·(m3·d)−1。汪瑶琪等[34]在小试19.6 L的反应器中,将好氧污泥和anammox种泥以2:1的体积比混合启动anammox工艺,耗时157 d,使NRR达0.44 kg·(m3·d)−1,本研究结果较其略有优势。JIN等[26]提出以NRR 达0.5 kg·(m3·d)−1为anammox反应器成功启动的标准,表明中试anammox工艺已成功启动。在反应器稳定运行时,ΔNO2−-N:ΔNO3−-N:ΔNH4+-N平均为1.16:0.06:1,低于厌氧氨氧化反应化学计量式,说明仍有一定的DNB共存[26]。

2.2 厌氧氨氧化反应器启动过程anammox菌丰度变化

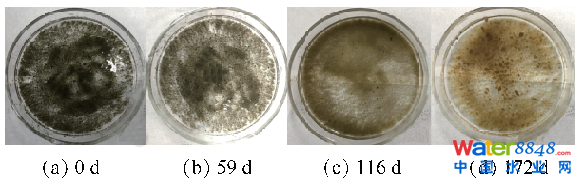

2.2.1 污泥颜色变化

由图4可知,初始接种时反应器内污泥颜色为墨黑色。经59 d厌氧驯化后,初显anammox活性的污泥颜色转为深灰色。随着anammox活性提高污泥颜色逐步变红,最终呈红棕色。MOLINUEVO等[37]研究发现,anammox菌因内部含有大量血红素C而呈现红色,在本研究中,泥色逐渐变红,进一步表明中试anammox工艺已成功启动。

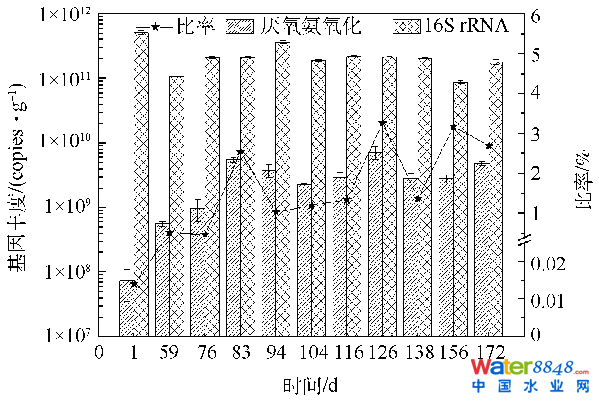

2.2.2 anammox菌丰度变化

由图5可知,随着anammox反应器运行时间延长,anammox菌基因丰度逐渐增加,最终丰度达4.92×109 copies·g−1 (以VSS计)。CHEN等[29]分别将反硝化和anammox种泥以3:1的体积比混合启动anammox工艺,成功启动时anammox菌基因丰度为4.13×109 copies·g−1。YIN等[9]采用添加氧化石墨烯的方式,促进anammox工艺的启动,启动成功时anammox菌基因丰度为1.84×109 copies·g−1。本研究结果高于二者成功启动时的anammox菌基因丰度。16S rRNA基因丰度无显著性变化,始终维持在(2.03±2)×1011 copies·g−1,anammox菌占16S rRNA的百分比由起初的0.01%渐增至2.70%。反应器运行1~59 d,anammox菌基因丰度由接种时的7.31×107 copies·g−1增至5.62×108 copies·g−1,增加了7.7倍。同时,16S rRNA基因丰度由5.20×1011copies·g−1下降至1.09×1011 copies·g−1,表明anammox菌开始逐步成为主要菌群之一[16]。经过60~172 d的活性提高,anammox菌占16S rRNA的百分比由之前的0.51%增加至2.70%。CHEN等[29]接种常规反硝化污泥启动anammox反应器,最终anammox菌占16S rRNA的百分比为3%左右。HU等[38]以接种水稻土启动SBR型anammox反应器,18个月后,anammox菌占16S rRNA的百分比约为5.3%。对比文献研究结果,从anammox菌绝对丰度和相对丰度两方面均表明anammox反应器已成功启动,且用时较HU等[38]缩短了6个月。

图5 厌氧氨氧化工艺启动中anammox菌基因丰度变化

Fig. 5 Changes in gene abundance of anammox bacteria during start-up of anammox process

Fig. 5 Changes in gene abundance of anammox bacteria during start-up of anammox process

2.3 厌氧氨氧化反应器快速启动中菌群多样性的变化

2.3.1 厌氧氨氧化反应器启动中Alpha多样性分析

厌氧氨氧化反应器启动过程中Alpha多样性指数的变化见表3。从表3可以看出,厌氧氨氧化反应器启动中高通量测序的4个样品覆盖率指数均高于0.99,表明检测结果基本涵盖所有微生物的16S rRNA基因[34]。表3中观察物种、Chao1和ACE指数表示样品中物种数量的多少,值越大,物种越丰富;Shannon、Simpson和PD whole tree指数表示微生物群落组成的复杂度,其值越高,复杂度越高[39-40]。随反应器NLR的提高,6种多样性指数总体呈下降的趋势,表明随着驯化时间的延长,反应器内微生物丰富度及复杂度降低。

表3 厌氧氨氧化反应器启动过程中Alpha多样性指数变化

Table 3 Alpha diversity analysis during start-up of anammox process in a pilot-scale reactor

Table 3 Alpha diversity analysis during start-up of anammox process in a pilot-scale reactor

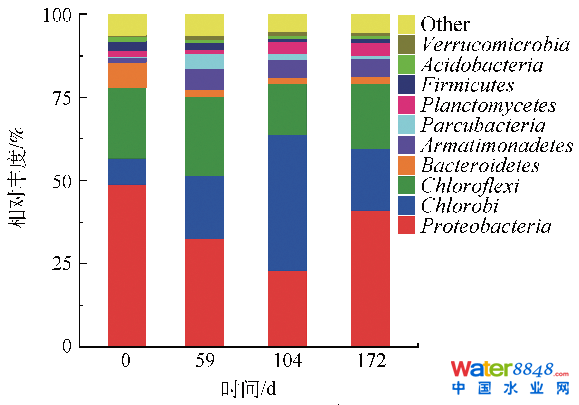

2.3.2 门水平物种丰度分析

由图6可知,反应器运行期间相对丰度较高的菌群主要有变形菌门(Proteobacteria)、绿菌门(Chlorobi)、绿弯菌门(Chloroflexi)、拟杆菌门(Bacteroidetes)、装甲菌门(Armatimonadetes)、Parcubacteria门、浮霉菌门(Planctomycetes)等。无论是在废水处理、厌氧消化还是土壤中,变形菌门均为最常见的贯穿始终的优势菌群[38,41-42],其丰度可在10.3%~55.5%间波动,为主要的脱氮功能菌群之一。本研究中,变形菌门相对丰度随反应器NLR的提升,呈先降后升的趋势。反应器运行0~104 d,由驯化初期的48.87%逐渐下降至22.92%,后于172 d时回升至41.02%,与CONNAN等[43]在anammox驯化过程中报道的变形菌门的变化趋势相同。绿弯菌门、拟杆菌门和装甲菌门是常见的可与anammox菌共存的菌群[44],同Parcubacteria门一起,其相对丰度均随驯化而先降低后上升,变化范围分别为15.48%~23.97%、1.80%~7.56%、1.47%~6.65%和0.26%~4.46%。CAO 等[16]对启动成功的anammox-UASB反应器内的污泥样品进行了群落结构分析,发现变形菌门、绿弯菌门、拟杆菌门、硝化螺旋菌门、酸杆菌门、装甲菌门、绿菌门和浮霉菌门为主要菌门,变形菌门和绿弯菌门占据比值分别为27.07%~32.24%和25.77%~29.14%,并指出绿弯菌门和拟杆菌门与污泥颗粒的形成相关。CONNAN等[43]研究报道,anammox反应器内微生物菌门主要为变形菌门、拟杆菌门、硬壁菌门、绿弯菌门、绿菌门、酸杆菌门和浮霉菌门,变形菌门丰度高达55.9%,绿弯菌门和绿菌门是anammox反应器内常见菌门。

浮霉菌门为主要的自养脱氮功能菌群,现在已知的具有厌氧氨氧化功能的微生物均属于浮霉菌门[45]。其变化趋势与变形菌门相反,随反应器NLR的提升,浮霉菌门相对丰度由0 d时的1.34%逐渐升高至172 d的3.64%,表明anammox菌得到了一定的富集。绿菌门相对丰度的变化趋势与浮霉菌门变化趋势一致。本研究结果与CAO 等[16]和CONNAN等[43]的结果相近,表明anammox颗粒污泥的形成可能受益于绿弯菌门、拟杆菌门、装甲菌门、绿菌门和Parcubacteria门丰度的增加。

图6 中试anammox反应器启动过程中主要菌群变化(门水平)

Fig. 6 Variation of main microbial flora at a phylum level during start-up of anammox process in a pilot-scale reactor

Fig. 6 Variation of main microbial flora at a phylum level during start-up of anammox process in a pilot-scale reactor

2.3.3 浮霉菌门中属水平物种丰度分析

为进一步了解anammox反应器启动中内部anammox菌的变化,选取浮霉菌门进行属水平的物种丰度分析。浮霉菌门主要有I-8、Candidatus Jettenia、Candidatus Kuenenia、SM1A02和Planctomyces等。在已知的具有厌氧氨氧化能力的6个属[45]中,本中试反应器检测到4个,分别是Candidatus Jettenia、Candidatus Kuenenia、Candidatus Brocadia和Candidatus Anammoximicrobium。

由表4可知,中试anammox反应器内Candidatus Jettenia和Candidatus Kuenenia为anammox的主要菌属。同时,两者也是污水处理厂和大规模anammox反应器中常见的2个属[46] 。之后随反应器内NLR逐渐增大,Candidatus Jettenia和Brocadia属丰度呈先增加后下降的趋势,反应器运行59~104 d,分别由13.50%和1.50%逐渐增至39.51%和1.72%,后于172 d时降至5.26%和0.20%。而Candidatus Kuenenia属丰度随NLR增大而逐渐增加,第172天时Kuenenia属丰度为第59 天时丰度的3.33倍,而Candidatus Anammoximicrobium属丰度随NLR增大而逐渐降低,第172 天时已检测不到,可能是因为Candidatus Kuenenia的生长速率、亚硝酸盐亲和力及对水质变化的抵抗力比其他anammox菌属强[47-48]。运行期间,anammox菌占总细菌的百分比逐渐增加,最高可达1.65%(Jettenia+Kuenenia+Brocadia+Anammoximicrobium)。实时定量PCR结果显示,在172 d时,anammox反应器中anammox菌的相对丰度为2.7%,与Illumina高通量测序结果接近,进一步印证了anammox工艺已快速启动。

表4 浮霉菌门中部分菌属的相对丰度变化

Table 4 Changes in relative abundance of some genus of planctomycetes

Table 4 Changes in relative abundance of some genus of planctomycetes

3 结论

1)在接种污泥处于anammox活性迟滞阶段时,投加富含anammox菌的种泥可以快速启动anammox反应器,且在anammox活性提高阶段,通过缩短HRT能够避免直接提高进水TN浓度带来的基质毒性抑制,可以更大程度上提高反应器氮去除负荷,启动成功后,anammox反应器最终NRR达0.51 kg·(m3·d)−1。

2)在启动过程中,接种污泥颜色由墨黑色逐渐变为红棕色,anammox菌丰度随NLR的增加逐渐上升,最终基因丰度达4.92×109copies·g−1 (以VSS计),占总细菌的2.70%。

3)在工艺启动阶段,anammox反应器内微生物复杂度逐渐降低,于浮霉菌门中检测到4个anammox菌属:Candidatus Jettenia、Candidatus Kuenenia、Candidatus Brocadia和Candidatus Anammoximicrobium属,占测序总数的1.65%,Candidatus Jettenia和Candidatus Kuenenia是反应器中主要的anammox菌属。

参考文献

- WR V D S, ABMA W R, BLOMMERS D, et al. Startup of reactors for anoxic ammonium oxidation: experiences from the first full-scale anammox reactor in Rotterdam[J]. Water Research,2007,41(18):4149-4163. [CrossRef]

- TANG C, PING Z, YI Y U, et al. Monosodium glutamate wastewater treatment with a full-scale SHARON reactor[J]. Acta Scientiae Circumstantiae,2008,28(11):2228-2235.

- DENG L W, ZHENG P, CHEN Z A. Anaerobic digestion and post-treatment of swine wastewater using IC-SBR process with bypass of raw wastewater[J]. Process Biochemistry,2006,41(4):965-969. [CrossRef]

- TANG C J, ZHENG P, CHEN T T, et al. Enhanced nitrogen removal from pharmaceutical wastewater using SBA-ANAMMOX process[J]. Water Research,2011,45(1):201-210. [CrossRef]

- LU Y F, MA L J, MA L, et al. Improvement of start-up and nitrogen removal of the anammox process in reactors inoculated with conventional activated sludge using biofilm carrier materials[J]. Environmental Technology,2017,39(1):59-67. [CrossRef]

- IBRAHIM M, YUSOF N, MOHD Z M Y, et al. Enrichment of anaerobic ammonium oxidation (anammox) bacteria for short start-up of the anammox process: A review[J]. Desalination & Water Treatment,2016,57(30):13958-13978. [CrossRef]

- CHAMCHOI N, NITISORAVUT S. Anammox enrichment from different conventional sludges[J]. Chemosphere,2007,66(11):2225-2232. [CrossRef]

- TAO Y, GAO D W, FU Y, et al. Impact of reactor configuration on anammox process start-up: MBR versus SBR[J]. Bioresource Technology,2012,104(1):73-80. [CrossRef]

- YIN X, QIAO S, ZHOU J, et al. Fast start-up of the anammox process with addition of reduced graphene oxides[J]. Chemical Engineering Journal,2016,283:160-166. [CrossRef]

- 唐崇俭, 郑平, 陈建伟,等. 中试厌氧氨氧化反应器的启动与调控[J]. 生物工程学报,2009,25(3):406-412.

- WANG G, XU X, ZHOU L, et al. A pilot-scale study on the start-up of partial nitrification-anammox process for anaerobic sludge digester liquor treatment[J]. Bioresource Technology,2017,241:181-189. [CrossRef]

- YE L, LI D, ZHANG J, et al. Fast start-up of anammox process with mixed activated sludge and settling option[J]. Environmental Technology,2017,19:1-8. [CrossRef]

- WANG T, ZHANG H, YANG F, et al. Start-up and long-term operation of the anammox process in a fixed bed reactor (FBR) filled with novel non-woven ring carriers[J]. Chemosphere, 2013,91(5):669-675. [CrossRef]

- WETT B. Solved upscaling problems for implementing deammonification of rejection water[J]. Water Science & Technology,2006,53(12):121-128. [CrossRef]

- WANG Y, MA X, ZHOU S, et al. Expression of the nirS, hzsA, and hdh genes in response to nitrite shock and recovery in candidatus kuenenia stuttgartiensis[J]. Environmental Science & Technology,2016,50(13):6940-6947. [CrossRef]

- CAO S, DU R, LI B, et al. High-throughput profiling of microbial community structures in an ANAMMOX-UASB reactor treating high-strength wastewater[J]. Applied Microbiology & Biotechnology,2016,100(14):6457-6467. [CrossRef]

- 曹雁, 王桐屿, 秦玉洁,等. 厌氧氨氧化反应器脱氮性能及细菌群落多样性分析[J]. 环境科学,2017,38(4):1544-1550. [CrossRef]

- HENDRICKX T L, KAMPMAN C, ZEEMAN G, et al. High specific activity for anammox bacteria enriched from activated sludge at 10°C[J]. Bioresource Technology,2014,163:214-221. [CrossRef]

- 国家环境保护总局. 水和废水监测分析方法[M].4版. 北京: 中国环境科学出版社,2002:211-213.

- TANG C J, ZHENG P, CHAI L Y, et al. Characterization and quantification of anammox start-up in UASB reactors seeded with conventional activated sludge[J]. International Biodeterioration & Biodegradation,2013,82(8):141-148. [CrossRef]

- HOU L, ZHENG Y, LIU M, et al. Anaerobic ammonium oxidation (anammox) bacterial diversity, abundance, and activity in marsh sediments of the Yangtze Estuary[J]. Journal of Geophysical Research Biogeosciences,2014,118(3):1237-1246. [CrossRef]

- LI M, HONG Y, KLOTZ M G, et al. A comparison of primer sets for detecting 16S rRNA and hydrazine oxidoreductase genes of anaerobic ammonium-oxidizing bacteria in marine sediments[J]. Applied Microbiology & Biotechnology,2010,86(2):781-790. [CrossRef]

- BAGCHI S, BISWAS R, ROYCHOUDHURY K, et al. Stable partial nitrification in an up-flow fixed-bed bioreactor under an oxygen-limiting environment[J]. Environmental Engineering Science,2009,26(8):1309-1318. [CrossRef]

- GUO J, WANG S, LIAN J, et al. Rapid start-up of the anammox process: Effects of five different sludge extracellular polymeric substances on the activity of anammox bacteria[J]. Bioresource Technology,2016,220:641-646. [CrossRef]

- BI Z, QIAO S, ZHOU J, et al. Fast start-up of anammox process with appropriate ferrous iron concentration[J]. Bioresource Technology,2014,170(5):506-512. [CrossRef]

- JIN R C, ZHENG P, HU A H, et al. Performance comparison of two anammox reactors: SBR and UBF[J]. Chemical Engineering Journal,2008,138(1):224-230. [CrossRef]

- STROUS M, HEIJNEN J J, KUENEN J G, et al. The sequencing batch reactor as a powerful tool for the study of slowly growing anaerobic ammonium-oxidizing microorganisms[J]. Applied Microbiology & Biotechnology,1998,50(5):589-596. [CrossRef]

- WANG S, GUO J, LIAN J, et al. Rapid start-up of the anammox process by denitrifying granular sludge and the mechanism of the anammox electron transport chain[J]. Biochemical Engineering Journal,2016,115:101-107. [CrossRef]

- CHEN H, HU H Y, CHEN Q Q, et al. Successful start-up of the anammox process: Influence of the seeding strategy on performance and granule properties[J]. Bioresource Technology,2016,211:594-602. [CrossRef]

- 陈光辉, 李军, 邓海亮,等. 包埋菌启动厌氧氨氧化反应器及其动力学性能[J]. 化工学报,2015,66(4):1459-1466. [CrossRef]

- PUYOL D, CARVAJALARROYO J M, SIERRAALVAREZ R, et al. Nitrite (not free nitrous acid) is the main inhibitor of the anammox process at common pH conditions.[J]. Biotechnology Letters,2014,36(3):547-551.

- ISAKA K, SUMINO T, TSUNEDA S. High nitrogen removal performance at moderately low temperature utilizing anaerobic ammonium oxidation reactions[J]. Journal of Bioscience & Bioengineering,2007,103(5):486-490. [CrossRef]

- DAPENA-MORA A, CAMPOS I F L. Evaluation of activity and inhibition effects on anammox process by batch tests based on the nitrogen gas production[J]. Enzyme & Microbial Technology,2007,40(4):859-865. [CrossRef]

- 汪瑶琪,张敏,姜滢,等.厌氧氨氧化启动过程及微生物群落结构特征[J]. 环境科学,2017,38(12):5184-5191.

- 孙佳晶. 厌氧氨氧化菌的富集培养及乙酸影响研究[D]. 辽宁:大连海洋大学, 2014.

- 秦永丽, 蒋永荣, 刘成良,等. Anammox启动过程中脱氮性能及污泥特性研究[J]. 环境科学与技术,2016,39(2):122-127.

- MOLINUEVO B, GARCIA M, KARAKASHEV D, et al. Anammox for ammonia removal from pig manure effluents: effect of organic matter content on process performance[J]. Bioresource Technology,2009,100(7):2171-2175. [CrossRef]

- HU M, WANG X, WEN X, et al. Microbial community structures in different wastewater treatment plants as revealed by 454-pyrosequencing analysis[J]. Bioresource Technology,2012,117(10):72-79. [CrossRef]

- SCHLOSS P D, GEVERS D, WESTCOTT S L. Reducing the effects of PCR amplification and sequencing artifacts on 16S rRNA-based studies[J]. Plos One,2011,6(12):e27310. [CrossRef]

- WANG Y, BU C N, KANG Q, et al. Autoclaved sludge as the ideal seed to culture anammox bacteria: Reactor performance and microbial community diversity[J]. Bioresource Technology,2017,244:391-399. [CrossRef]

- RIVIÉRE D, DESVIGNES V, PELLETIER E, et al. Towards the definition of a core of microorganisms involved in anaerobic digestion of sludge[J]. ISME Journal,2009,3(6):700-714. [CrossRef]

- FIERER N, BRADFORD M A, JACKSON R B. Toward an ecological classification of soil bacteria[J]. Ecology,2007,88(6):1354-1364. [CrossRef]

- CONNAN R, DABERT P, KHALIL H, et al. Batch enrichment of anammox bacteria and study of the underlying microbial community dynamics[J]. Chemical Engineering Journal,2016,297:217-228. [CrossRef]

- KINDAICHI T, YURI S, OZAKI N, et al. Ecophysiological role and function of uncultured Chloroflexi in an anammox reactor[J]. Water Science & Technology,2012,66(12):2556-2561. [CrossRef]

- ALI M, OKABE S. Anammox-based technologies for nitrogen removal: Advances in process start-up and remaining issues[J]. Chemosphere,2015,141:144-153. [CrossRef]

- KUENEN J G. Anammox bacteria: from discovery to application[J]. Nature Reviews Microbiology,2008,6(4):320-326. [CrossRef]

- WR V D S, MICLEA A I, VAN DONGEN U G, et al. The membrane bioreactor: A novel tool to grow anammox bacteria as free cells[J]. Biotechnology & Bioengineering,2008,101(2):286-294. [CrossRef]

- ISAKA K, SUWA Y, KIMURA Y, et al. Anaerobic ammonium oxidation (anammox) irreversibly inhibited by methanol[J]. Applied Microbiology & Biotechnology,2008,81(2):379-385. [CrossRef]